Inside Ocado's burning robotic warehouse

BBC

BBCWalking into the first chamber of Ocado's robot warehouse system in May, I was immediately struck by three things: how cold it was, how enormous it was, and how quiet.

No shouts from warehouse staff, or tinny radios playing pop hits. No beeps from reversing forklift trucks.

Just the swoosh of wheels from 1,100 waist-high cuboid swarm robots, zipping along a grid system the size of several football pitches.

The entire site spans 18 acres (784,080 sq ft). The robots collect groceries from crates beneath them, and drop them off at a packing station.

Occasionally they would all simultaneously come to a halt, green lights blinking, awaiting their next command, received via an unofficial 4G network custom-built by Ocado.

Allow X content?

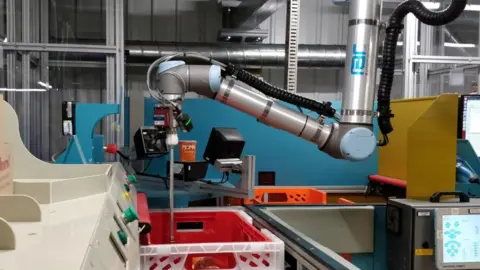

Underneath them, side-by-side with humans, another robot consisting of only one arm was being trained to pack the goods gathered by the swarm to fulfil individual orders.

It felt futuristic, and a little spine-tingling.

I could feel the chill despite my thick scarf and the heavily padded high-vis jacket I was given to wear. The temperature was to protect the cold food, I was told.

But let's not forget there's a good reason why data centres full of computer servers are often built inside icy mountains or under oceans. Electronics get hot.

I had been hassling the grocery retailer Ocado for months for a tour of its Andover warehouse in the south of the UK. No visits were planned, the press officer kept telling me.

I was frustrated because Ocado is a significant tech firm in its own right. It has invested millions in developing robotics with the ambition of becoming a people-free platform.

That means that from the moment you place your online order to the moment it arrives at your door (via a driverless van of course), there will be no human intervention. And this vision was starting to play out in the firm's Andover warehouse.

Whatever your thoughts about the impact on human jobs, the robots were certainly busy. The plant was processing 65,000 orders per week.

Finally, I got my invitation. Thanks to train problems I almost didn't make it. I missed the "official" tour, although this meant I got my own private guide.

Ocado's chief technology officer Paul Clarke was proud of the swarm robots. He explained they were actually all part of the same machine.

My guide (who was not Mr Clarke) described them as part-robot, part-phone, because of their 4G communications.

Mr Clarke told me that he thought customers would be "surprised" by the level of automation behind their grocery shopping.

Other supermarkets were extremely interested in the Ocado blueprint. By the time I saw it in action, it had already been licensed to Morrisons supermarket in the UK, Groupe Casino in France and the Sobeys chain in Canada.

PA

PABut on Tuesday 5 February, the warehouse caught fire. Within hours it was declared a "major incident" with 200 firefighters tackling the blaze.

By Wednesday night, local homes were being evacuated. On Thursday morning, locals say an acrid smell lingers over the area. The fire is only now being dampened down, helped by a rain shower.

I spoke to a contact at Ocado who expressed shock at how the fire had spread so fast.

The sprinkler system had won a global award. It was recognised as being one of the best in the world, and it appears to have activated correctly, I heard.

Fortunately nobody was hurt.

The firm has not yet commented on the probable cause of the blaze and the investigation could go on for quite some time.

I posted a picture on Instagram that I took on the day of my visit.

"One of the pitfalls of a robot-only workplace: they can't smell the smoke when said workplace is on fire," wrote one commenter.