Cardboard shortage forces retailers to box clever

Basil Hassan

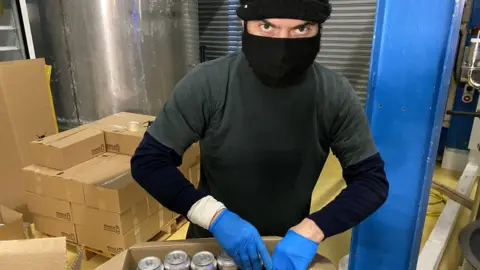

Basil HassanJawbone Brewing, a newly launched craft brewery in Twickenham, south-west London, was all ready with its new pale ale when it came across a stumbling block.

It couldn't get hold of any boxes.

The boom in online ordering during the pandemic has also meant rocketing demand for cardboard, as consumers have started taking delivery of everything from bicycles to houseplants.

In the end Jawbone had to delay the launch of online deliveries by three weeks while the company looked for packaging.

They put out a plea to local customers on social media: could you bring a box with you? And founder Ben Hughes went on a mad scramble to find the right kind of double-walled delivery boxes that would protect the cans of beer adequately in the post.

"I wanted to get the boxes branded. But we haven't been able to. All the suppliers are saying you have to wait a few months for that."

BusinessWaste.co.uk

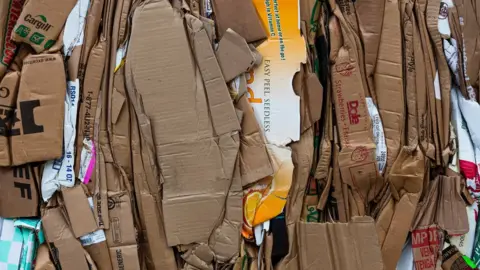

BusinessWaste.co.ukThe Confederation of Paper Industries (CPI) says while there is always a peak in demand in the run up to Christmas, stockpiling around the Brexit deadline exacerbated the problem. Covid-19 also led to complications with shipping and staffing challenges, which affected the industry on a global basis.

The CPI described it as a "perfect storm" but said new capacity coming on stream would help ease the pressure.

Multinational packaging firm, DS Smith, said the problem lies partly in the recycling chain. Pre-pandemic when most deliveries were made in bulk to High Street shops and restaurants, packaging found its way quickly back into the system via recycling firms.

Disappointed customers

"All our boxes are made from recycled material," said group chief executive Miles Roberts.

"One of the challenges for us is that, with so much packaging now in peoples homes or in their garages, how do we get that paper back into the recycled network, how we can get it back into our mills so we can convert it into paper and reuse it again?"

Richard Ellison had to explain the problems to some disappointed customers. About 100 customers, expecting a next-day delivery of organic wine from Wanderlust Wine, saw their orders slip by a day or two.

Wanderlust

WanderlustSome were "massively hacked off", he says. Like Jawbone, Wanderlust Wine had run short of packaging.

"We were warned there was a shortage of raw materials," says Mr Ellison. Prices jumped and the lead time on orders went from a week to three months.

"That's a huge lead time to get boxes made," he says. He ended up buying 3,000 boxes at double the cost, he says. And now he's switched to using non-branded standard boxes rather than the bespoke ones designed for Wanderlust.

Even supermarkets are feeling the pinch with Asda, Lidl and the Co-op, finding they had to switch to plastic boxes for their eggs for the same reason, prompting criticism on social media.

"There is a shortage of the pulp used to make the cardboard boxes that is affecting all retailers. These plastic ones are 100% recyclable but we hope to go back to the cardboard ones as soon as we can," Asda responded on Twitter.

Axl Barber, boss of packaging firm Rightbox, says the problems started back in October but now "it's really crazy".

"A standard box with flaps at top and bottom can get made up in days and delivered in a week in a normal times," he says. "At the moment it's two months, three months."

He's helping small firms find solutions on a case-by-case basis, using whatever boxes can be found. One firm selling PPE resorted to using boxes without lids by wrapping them thoroughly.

Some firms are blaming the suppliers of raw materials themselves, others point the finger at the retail behemoths, like Amazon for taking more than their fair share.

Amazon said it has been reducing the amount of packaging it uses in recent years, including sometimes shipping products in their own packages without additional "shipping boxes".