The teatime snack helping save the planet

La Creme Patisserie

La Creme PatisserieThey say your pudding will spoil your tea, but it turns out cream cakes could also save the salmon in your sandwiches.

Waste water from a south Wales patisserie is being used to grow bacteria which can replace chemical fertilisers in farming, reducing both water and air pollution.

La Creme Patisserie makes about 50,000 handmade desserts a week from their Cwmbran base for clients ranging from Cheltenham Racecourse to Liverpool FC, and even the royal palaces.

Now their waste water is being used by a biotech firm to make pollution-busting bacterial pellets after the two unlikely partners were brought together by Swansea University.

La Creme Patisserie's frozen cakes are precision-cut by high pressure water saws which create 250,000 litres annually of high-nutrient "effluent".

Until recently, this waste water then had to be processed in water treatment plants.

However, Lux Biotech, based in Baglan, Neath Port Talbot, now use the effluent - rich in carbohydrates, proteins and fats – to make their pollution-busting bacterial pellets which can either be ploughed into soil, or act as a water filtration system.

Lux Biotech Ltd

Lux Biotech LtdChris Charles, founder of Lux Biotech, said the company grow three types of bacteria which are suitable for organic farms.

These are used to fix nitrogen into the soil, increase crop yields, and reduce ammonia and nitrous oxide emissions into the atmosphere and waterways.

"Along the River Wye here in Wales in particular, we have a huge problem with agricultural run-off from poultry farms which promotes the growth of algae, sucking up oxygen from the water and strangling aquatic life," he said.

"But it's even better than that, because until now treating the cream cake effluent created six tons of CO2 per year, and used a quarter of a million litres of water. With our partnership we've removed that energy-intensive process, and the water is repurposed."

Lux Biotech Ltd

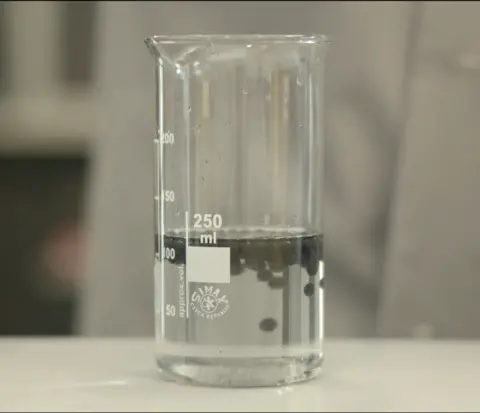

Lux Biotech LtdDr Charles said effluent water is pumped directly into a reactor at La Creme Patisserie's Cwmbran factory, where the spores are added and "cooked" for two days.

The nutrients provide the ideal food to grow three varieties of bacteria - glutamicibacter, pseudomonas veronii and sphingobium - which all occur naturally in soil but are more effective at higher concentrations.

From the reactor, the bacteria is grafted onto a form of charcoal called biochar, where its porous cavities provide a habitat for colonisation.

The pellets are then encased in 3mm beads formed from a species of seaweed.

Lux Biotech and La Creme Patisserie were brought together by Swansea University's Applied Research for Circular Solutions (ARCS) project, which works with businesses across Swansea, Neath Port Talbot, Carmarthenshire and Pembrokeshire to support the introduction of circular economy ventures, reducing waste and costs.

Hannah Morris, research and innovation fellow for ARCS, likened her role to a "sort of dating agency for companies".

"I think that's one of the nice things isn't it? It's finding those opportunities for industrial symbiosis – you have something to dispose of, we know somebody who could make use of it – it's really great to take the research and bring it to life," she said.

"As well as this partnership, we're working on ways to repurpose plastic packaging, bale waste from music festivals on-site to make it easier to transport, and using stone dust from quarries to make a more environmentally-friendly alternative to concrete."

La Creme Patisserie

La Creme PatisserieRob Hindle, operations director for La Creme Patisserie, added: "We've been a family-run firm for over 20 years, we're massively proud of our locally-sourced ingredients and the customers who trust in us.

"Thanks to our partnership with Lux Biotech and ARCS, we can now also be proud of our efforts to be an ethical and sustainable business, reducing our footprint, saving on costs and hopefully giving clients another reason to choose us."

According to Dr Charles, this is just the start.

"The technology itself isn't that new, but until we found a suitable source of food waste it just wasn't financially viable," he said.

"We're still in the pre-revenue stage, but thanks to ARCS we can scale it up and look at other ways of utilising it. The bacteria love cream cakes, but they can adapt to any food stuff, so wherever there's a take-away or a brewery for example, we can grow them."

Dr Charles said there was no reason why, "given sufficient capacity", the firm couldn't make enough beads to make them available for home gardeners to buy at DIY stores like B&Q, Homebase or Dobbies "in a few years' time".